The Chrome Market

Critical Minerals and The Energy Transition

Navigating the Chromium Market

Chromium is a hard, lustrous transition metal best known for its exceptional corrosion resistance, high-temperature stability, and role in producing stainless steel. As a critical alloying element, it imparts strength, hardness, and oxidation resistance to a wide range of structural and high-performance materials. Chromium’s metallurgical properties are indispensable to defence systems, aerospace components, chemical processing equipment, and energy infrastructure. Beyond its primary use in stainless steel—accounting for more than 85 percent of global demand—chromium also plays a vital role in coatings, pigments, catalysts, and emerging battery chemistries. With global supply concentrated in South Africa, Kazakhstan, Turkey, and India, and with certain forms of chromium classified as critical under EU and US strategic raw material frameworks, the metal’s importance extends beyond industrial demand to national security and supply chain resilience. As global efforts intensify to modernise infrastructure, decarbonise heavy industry, and secure materials essential to manufacturing sovereignty, chromium’s strategic relevance continues to expand.

An introduction to chromium

Chromium demand and end-uses

Chromium is a critical industrial metal primarily used for its exceptional corrosion resistance, hardness, and high-temperature performance. Its unique properties arise from its ability to form a stable, self-healing oxide layer when exposed to oxygen, making it essential to the integrity and longevity of metallic structures and coatings. Chromium’s demand is overwhelmingly dominated by the metallurgical sector, yet it also plays strategic roles in aerospace alloys, defence-grade components, catalysis, pigments, and emerging battery chemistries. As decarbonisation and infrastructure modernisation accelerate globally, chromium’s cross-sectoral relevance is increasing, particularly in energy, transport, and manufacturing supply chains.

The largest end-use of chromium, accounting for more >85% of global consumption, is in the production of stainless steel. Chromium is the defining alloying element in stainless steel, typically used at concentrations of 10.5% or higher to confer corrosion and oxidation resistance. Austenitic stainless steels, which contain both chromium and nickel, are widely used in construction, transportation, food processing, healthcare, and industrial equipment. Ferritic and martensitic grades, with higher chromium and lower nickel content, are deployed in automotive components, energy systems, and domestic appliances. As demand for low-maintenance, long-life infrastructure grows, especially in coastal and corrosive environments, stainless steel consumption continues to underpin global chromium demand.

Beyond stainless steel, chromium is used in the manufacture of superalloys and high-strength steels for aerospace, defence, and high-temperature industrial applications. Chromium-containing nickel-base and cobalt-base superalloys are essential for turbine blades, jet engines, and advanced propulsion systems, where thermal stability and resistance to creep, oxidation, and fatigue are mission-critical. Chromium is also a key component in armour plating, ballistic-resistant steels, and defence-grade fasteners and structural materials. These applications require precise control of alloy chemistry to balance hardness with ductility under extreme operating conditions.

In the chemical sector, chromium compounds are used in catalysts, tanning agents, pigments, and wood preservatives. Chromium(VI) compounds, despite their toxicity, remain important in niche catalytic processes and metal finishing, though regulatory restrictions are accelerating the shift toward trivalent chromium alternatives. Chromium(III) compounds, particularly chromium oxide, are used in ceramic glazes, abrasives, and refractory bricks, especially for glass, cement, and steelmaking furnaces. These bricks provide critical thermal insulation and chemical durability, extending furnace lifespans and improving energy efficiency in high-temperature processes.

Electroplating is another major industrial use of chromium, particularly in decorative and functional coatings applied to automotive trim, aerospace components, tools, and household fixtures. Chromium electroplating offers hardness, wear resistance, and corrosion protection. While environmental and health concerns over hexavalent chromium have led to tighter regulations, the industry is transitioning toward safer trivalent chromium plating technologies, maintaining functional demand across high-value manufacturing sectors.

In the energy sector, chromium plays a supporting role in heat- and corrosion-resistant alloys used in power plants, oil and gas pipelines, nuclear containment systems, and renewable energy infrastructure. Chromium-bearing steels are used in solar thermal power stations, hydroelectric components, and next-generation power grid hardware due to their mechanical resilience and weathering resistance. In nuclear applications, chromium is being researched for accident-tolerant cladding and corrosion-resistant fuel rod coatings in both fission and emerging fusion systems.

Emerging demand for chromium is also being observed in battery technologies, particularly in research on chromium-based redox flow batteries and sodium-ion systems. Chromium’s multiple oxidation states make it suitable for electrochemical cycling, though these technologies remain pre-commercial. If scaled, they could provide long-duration grid storage solutions essential to renewable energy integration, potentially expanding chromium’s role in the energy transition.

In the automotive sector, chromium-containing high-strength steels are used in structural frames, crankshafts, gears, and engine valves, where fatigue resistance and thermal performance are essential. Chromium plating also remains prevalent in decorative finishes and under-hood components requiring durability and corrosion protection. The shift toward electric vehicles is likely to reduce some demand from internal combustion components but may support growth in high-performance chassis and drivetrain alloys.

Medical and dental applications of chromium include surgical instruments, implants, and prosthetics, typically made from chromium-rich stainless steels or cobalt-chromium alloys. These materials combine biocompatibility with high mechanical strength and corrosion resistance, supporting long-term implantation and sterilisation performance. Chromium’s role in health technologies, while modest in volume, is essential to patient safety and device reliability.

Pigments and ceramics also account for a modest but consistent share of demand, with chromium compounds used to produce vibrant greens, reds, and blacks in paints, inks, and coloured glass. Although some pigment use is being replaced due to toxicity concerns, demand persists in refractory ceramics, high-end construction materials, and artist-grade products where colourfastness and chemical resistance are valued.

As regulatory environments evolve and strategic sectors pursue material efficiency and durability, chromium’s relevance is expanding beyond bulk stainless steel into domains critical to national infrastructure, decarbonisation, and technological sovereignty. Ensuring secure and sustainable chromium supply will be vital to supporting resilient industrial ecosystems in a multipolar and resource-constrained world.

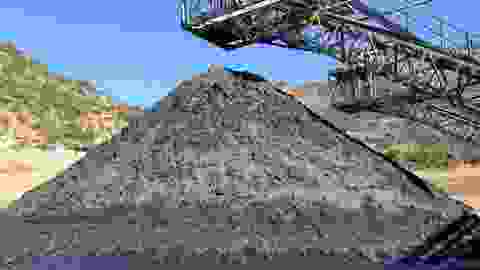

Chromium supply

Chromium supply is globally concentrated and geopolitically exposed, with over 75 percent of global primary production sourced from just three countries: South Africa, Kazakhstan, and Turkey. These nations dominate the extraction of chromite (FeCr₂O₄), the principal ore of chromium, which is processed into ferrochrome, an intermediate alloy used in stainless steel and other chromium-bearing alloys. South Africa alone accounts for more than half of global ferrochrome output, making it the central node in chromium’s raw material chain. Other producers such as India, Finland, Zimbabwe, and Brazil contribute smaller but strategically significant volumes. This concentration of supply, combined with variable trade policies, energy constraints, and ESG factors, introduces a high level of structural risk to the chromium value chain.

Chromium is not mined in its metallic form. Instead, it is produced through the mining of chromite ore, which is typically processed via pyrometallurgical smelting to produce ferrochrome, a high-carbon or low-carbon iron-chromium alloy used predominantly in stainless steelmaking. Metallurgical-grade chromite accounts for the majority of global demand, but chemical-grade and foundry-grade ores are also mined for niche applications in refractories, pigments, and catalyst production. The quality of chromite ore—measured in chromium-to-iron ratio (Cr:Fe) and Cr₂O₃ content, strongly influences its downstream use and commercial value.

In South Africa, chromite is sourced not only from dedicated open-cast and underground chromite mines, but increasingly from the UG2 reef, which is primarily mined for platinum group metals (PGMs). The UG2 ore body contains significant quantities of fine-grained chromite, which is recovered as a by-product during PGM extraction. This UG2-associated chromite has become an important component of the global supply base, offering metallurgical-grade feedstock with high Cr₂O₃ content. However, as UG2 mining is driven primarily by platinum and palladium markets, chromium output from these operations is subject to fluctuations in PGM pricing, operational throughput, and processing economics. This co-product dependency adds another layer of complexity and supply risk, particularly as PGM producers adjust their output in response to changing market conditions.

South Africa’s broader chromite and ferrochrome industry is increasingly affected by energy insecurity, ageing infrastructure, and policy uncertainty. Eskom’s electricity shortages and rising tariffs have reduced ferrochrome smelting margins, prompting some producers to idle capacity or defer expansion. In parallel, South African ferrochrome producers face cost competition from Chinese smelters, which import raw chromite, often sourced from South Africa or Turkey, and process it under looser environmental regulations. This has led to calls within South Africa for export restrictions on raw chromite, aimed at supporting local beneficiation, though such measures risk disrupting global trade flows and price stability.

Kazakhstan is another key producer, with chromite mined primarily by TNC Kazchrome, a subsidiary of Eurasian Resources Group. Kazakh production benefits from vertically integrated operations and favourable logistics for export to China, Russia, and Europe. However, Kazakhstan’s alignment with Russia and regional geopolitical instability present growing uncertainty for Western supply chains. Turkey, the third major source, supplies high-grade lumpy chromite ores and exports significant volumes to China and Europe. Its mining sector remains attractive for small- and mid-sized operations but is exposed to regulatory changes and economic volatility.

China, while possessing limited domestic chromite reserves, is the world’s largest ferrochrome importer and stainless steel producer, creating an asymmetrical dependence on external supply. To reduce vulnerability, China has pursued upstream investments in Africa and Asia, including joint ventures in South Africa, Zimbabwe, and Pakistan. This strategy reflects a broader trend of resource-backed diplomacy and vertical integration, with implications for global chromium trade flows and access for Western buyers.

Secondary supply of chromium is limited relative to primary production. Recycling of stainless steel provides a modest but growing share of chromium units, particularly in developed economies with mature scrap collection systems. However, most recycled chromium is reused in bulk form, and recovery from fine-scale applications such as electroplating or chemical catalysts is technically complex and economically constrained. While circular economy initiatives are expanding, secondary chromium remains a supplementary, not dominant, supply source.

Environmental, social, and governance (ESG) considerations are increasingly shaping the outlook for chromium supply. Chromium(VI) compounds, used in some chemical and plating applications, are classified as carcinogenic and face tightening regulation in the EU and other jurisdictions. While chromium metal itself and Cr(III) compounds used in alloys are generally considered safe, the overall environmental footprint of ferrochrome production—particularly in coal-powered smelters—remains significant. This is prompting pressure for decarbonisation, water management, and traceability standards across the supply chain, particularly from automotive, aerospace, and green infrastructure sectors seeking low-carbon materials.

Supply risks are further amplified by trade policy dynamics, including export taxes, beneficiation mandates, and resource nationalism. South Africa has considered restricting raw chromite exports to encourage domestic ferrochrome production, while Indonesia and India have periodically imposed duties or quotas on chromite exports. These measures, while aimed at value retention, can disrupt global availability and pricing, especially for chemical- and refractory-grade feedstocks with narrower sourcing options.

Given chromium’s critical role in stainless steel, military-grade alloys, nuclear energy systems, and refractory applications, ensuring secure and sustainable supply has become a strategic priority for a growing number of governments. The EU has included chromium compounds on its Critical Raw Materials list, while the US has designated chromium as a critical mineral due to its essentiality and import dependence. Stockpiling, trade diversification, and investment in recycling and substitution R&D are increasingly seen as necessary tools to mitigate geopolitical and supply-side risks.

Current production of chromium ores and concentrates

Chromium substitution

Chromium’s widespread use across metallurgical, chemical, and industrial sectors is driven by its unique ability to impart corrosion resistance, hardness, and high-temperature stability. As a result, substitution is often technically constrained, particularly in applications where material performance, regulatory compliance, and product lifespan are critical. Nonetheless, substitution pressures have intensified in response to volatile pricing, toxicological concerns, particularly around hexavalent chromium (Cr⁶⁺)—and the strategic concentration of supply. While partial substitution is feasible in certain sectors, wholesale displacement of chromium often results in reduced performance, increased lifecycle costs, or greater environmental burden.

In stainless steel production, which accounts for >85% of global chromium demand, substitution options are highly limited. Chromium is the defining alloying element in stainless steels, particularly in austenitic, ferritic, and martensitic grades. Reducing chromium content below 10.5% typically results in a loss of corrosion resistance and structural integrity, disqualifying the steel from stainless classification. In cost-sensitive or non-corrosive environments, aluminium or carbon steels may substitute for stainless steel, but these alternatives require additional protective coatings or surface treatments, increasing maintenance needs and reducing durability. In some applications, duplex stainless steels can reduce total chromium content by blending phases, but this requires careful control of alloying elements such as nitrogen, molybdenum, and nickel.

In superalloys and high-performance steels, chromium is critical to oxidation resistance, strength, and fatigue life in extreme environments. In aerospace turbines, nuclear components, and military armour plating, partial substitution with elements such as molybdenum, silicon, or aluminium may be viable in specific alloy systems, but these often trade off corrosion resistance or weldability. Cobalt- or nickel-based alternatives can also substitute in some high-temperature settings, but they are typically more expensive, less abundant, and themselves exposed to strategic supply risk. As a result, substitution in defence-grade and high-performance alloy systems remains highly application-specific and limited.

In the chemical sector, substitution is more advanced in response to environmental regulation. Hexavalent chromium (Cr⁶⁺) compounds, formerly used in pigments, leather tanning, and wood preservatives, are being replaced with less toxic alternatives. In tanning, vegetable tannins, synthetic polymers, and aldehyde-based agents have displaced chromium in some markets, though at the cost of longer processing times or reduced leather stability. In wood protection, copper-based systems and borates are gaining traction, albeit with limited durability in some climates.

In pigments, chromium oxides have traditionally delivered vibrant green and red colours with excellent UV and chemical resistance. Substitutes such as cobalt-based blues and greens, organic pigments, and cerium or iron oxides are increasingly used, especially in paints and coatings where regulatory restrictions apply. However, alternatives may lack thermal stability or fade more rapidly under environmental exposure, particularly in ceramics, glass, and high-temperature coatings.

In electroplating, hexavalent chromium is widely used for decorative and functional coatings. The transition to trivalent chromium plating systems has accelerated due to EU REACH regulations and similar global frameworks. Trivalent systems offer improved safety and lower environmental impact, but often require more complex control parameters and may yield slightly different surface finishes. In some industrial settings, substitutes such as nickel-tungsten alloys, cobalt-phosphorus coatings, or PVD (physical vapour deposition) techniques can replace chromium plating, though they typically involve higher equipment costs or process changes.

In refractory applications, where chromium-containing bricks are used in glass furnaces, cement kilns, and steelmaking, substitution is constrained by thermal shock resistance and slag compatibility. Alternatives such as magnesia-alumina spinels, zirconia-based bricks, or silicon carbide can replace chromium in certain environments but may shorten refractory life or alter process dynamics. Glass producers, in particular, are exploring chrome-free furnace designs to meet stricter emission controls, but uptake is gradual and often dependent on furnace type and product grade.

In emerging energy technologies, chromium substitution is under investigation but remains limited. In solar thermal plants and nuclear reactors, high-chromium alloys provide essential oxidation resistance. Research into accident-tolerant fuels and advanced cladding materials explores coatings with silicon carbide, aluminium alloys, or chromium-free ceramics, but these are still largely at the R&D or pilot stage. In battery technologies, chromium-based redox flow systems have some potential substitution overlap with vanadium and iron-based chemistries, though each system offers distinct electrochemical performance and storage characteristics.

In medical and dental alloys, cobalt-chromium systems are sometimes substituted with titanium, nickel-free stainless steels, or ceramics, depending on biocompatibility and application requirements. While chromium-free implants are available, especially for allergy-prone patients, chromium remains preferred in many structural implants and surgical tools due to its strength, sterilisation compatibility, and resistance to degradation.

Overall, chromium substitution is technically viable in certain chemical and surface coating applications, especially where health and environmental regulation mandate alternatives. However, in structural, metallurgical, and high-performance contexts, chromium remains largely irreplaceable due to its unique combination of corrosion resistance, strength, and thermal performance. As regulatory pressure increases and ESG standards evolve, substitution will likely be accompanied by increased demand for chromium-efficient technologies, advanced recycling, and low-emission processing pathways rather than wholesale material displacement.

Ferrochrome producers

Linked chrome market reports

The Long-term Chrome Market Outlook

Our bespoke chrome report gives our latest view on supply, demand, and pricing out to 2026 and analyses the impact of chrome on mine profitability.

Meet the Chrome team

Ismet Soyocak

ESG & Critical Minerals Lead

Alex Biddle

Senior Mining Analyst

Franklin Avery

Commodity Analyst

How can we help you?

SFA (Oxford) provides bespoke, independent intelligence on the strategic metal markets, specifically tailored to your needs. To find out more about what we can offer you, please contact us.